Customer company

Fagerhult

The story

When two Nordic pioneers join forces, the result is more than a product—it’s a

leap forward for sustainable lighting. In a close collaboration with Fagerhult,

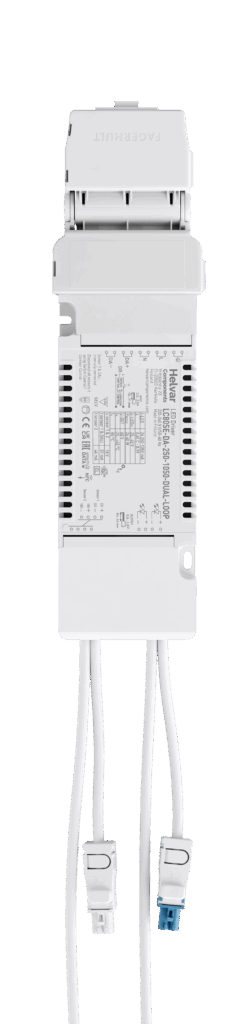

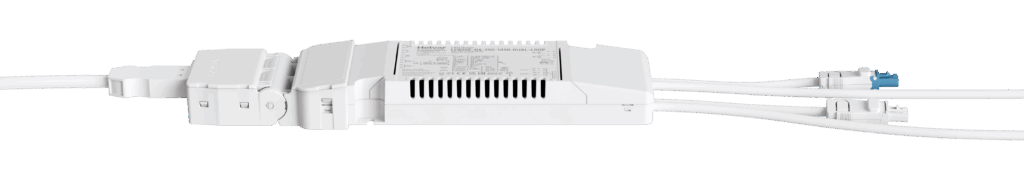

Helvar Components engineered a completely new, specification‑built LED driver

that challenges convention and cuts carbon: the

LC80SE-DA-250-1050-DUAL-LOOP.

The challenge

- Reduce the number of drivers per installation without compromising safety,

control, or light quality. - Streamline installation and commissioning at scale.

- Lower total environmental impact across materials, electronics, and logistics.

© 2025 Fagerhult Belysning AB

“To make this vision a reality, we needed a strong development partner. We reached out to Helvar Components, and their response was very positive. After a few initial meetings, we quickly aligned on specifications, volumes, timelines, and cost levels. The overall development time was short, largely due to the time required to create the new housing tools.”

Kenneth Rudenbrandt | Technical Product Manager, Fagerhult

The solution

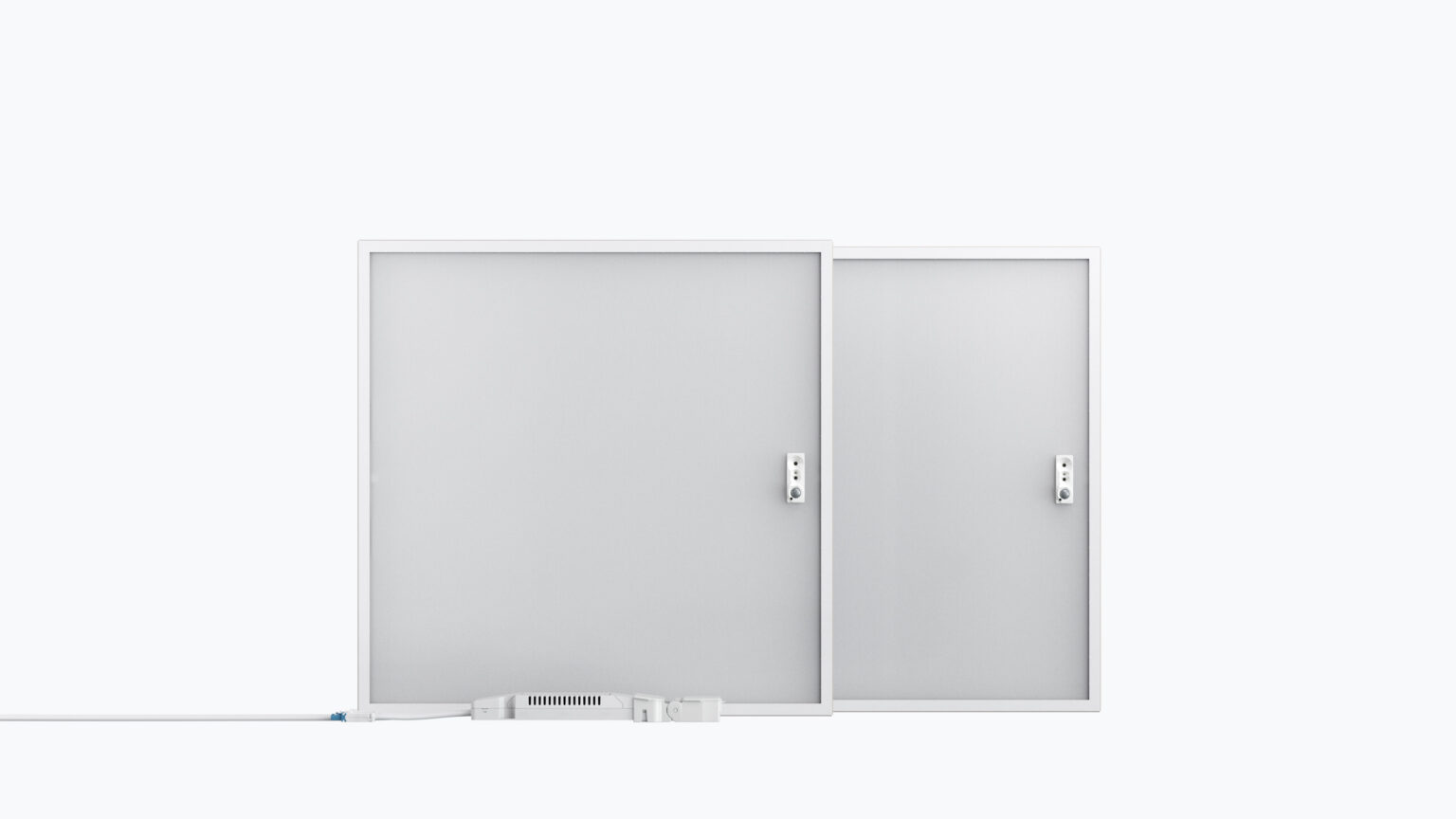

Co-created with Fagerhult, our DUAL-LOOP model powers two independent luminaires from a single driver—while remaining fully compatible with sensors and advanced controls. A major technical challenge during the development process was ensuring that both luminaire channels can keep operating independently regardless of the other – even accounting for LED panel fault situations or small variances in LED load voltages across twin channels.

Feature set that makes this solution one of its kind

- Two luminaires, one LED driver: Connect two LED panels or luminaires to a single driver with up to several meters of separation, reducing electronics and cabling. What is unique in this solution – if one luminaire fails, the other continues its operation normally. This means that DUAL-LOOP LED driver can be used also with just single luminaire.

- Ready for sensor intelligence: Native support for sensor integration and responsive lighting control, enabling synchronised behaviour across both luminaires.

- Half the DALI addresses: Shared DALI addressing for two luminaires halves the need for separate addresses. This decreases the need for DALI subnets and routers as well as minimises commissioning efforts.

- Recycled plastic housing: Materials were chosen to support the circular economy, reducing the environmental impact even further.

Measured sustainability impact

Paired with Fagerhult’s luminaires in their study, the co-developed solution achieved a 49% reduction in overall CO2e for the LED driver part compared to two conventional drivers with equivalent functionality (EPD, GWP Fossil A1–A3)*. Fewer LED drivers mean less materials, less transport, and lower energy use across the lifecycle—without sacrificing performance.

Why it matters in the Nordics (and beyond)

From Karkkila, Finland to Habo, Sweden, we share the same mission: tangible, scalable climate

action. In regions where lighting and heating demand is high, every watt and every component

counts. Fewer LED drivers, fewer installation hours, less commissioning—and significantly

less CO2—add up to more value for customers and the planet.

In the field, Fagerhult’s Twin Dual Driver brings the DUAL-LOOP idea to life across multiple

luminaire families, enabling seamless integration with Organic Response for synchronised

control and flexible cable lengths and quick connection systems for faster rollouts.

*Fagerhult Belysning 2025.

The results

- Double the luminaires per driver

- Up to 49 % reduction in total driver CO2e

- Faster installation and commissioning

- 50 % less of the DALI addresses used per system compared to one driver per luminaire setups

- High-quality LED driver with Smart Data banks (DALI 251-253) and readiness for sensor connection

What began as a simple question—“Can we do more with less?”—became a joint development program, rigorous testing, and finally a market-ready solution that redefines how drivers power today’s luminaires.

© 2025 Fagerhult Belysning AB

Comments from the project

“After the successful launch of our Multilume Re:think luminaire, made from solid board, we held a meeting in our R&D department to discuss a key question: “What more can we do to improve sustainability?”

We recognised that electronics have a significant environmental impact, and we asked ourselves how we could reduce it. Where in our portfolio could we make the biggest difference? The answer was clear — recessed products.

This led to the idea of developing a DUAL/TWIN driver for larger downlights and flat panels. We also wanted to include smart control capabilities, such as Organic Response sensors, resulting in a D4i driver.

To make this vision a reality, we needed a strong development partner. We reached out to Helvar Components, and their response was very positive. After a few initial meetings, we quickly aligned on specifications, volumes, timelines, and cost levels. The overall development time was short, largely due to the time required to create the new housing tools.

Today, nearly all our recessed products are available with the DUAL/TWIN driver.

In combination with our Multilume Re:think luminaires, this driver represents Fagerhult’s best current solution for reducing climate impact.”

Kenneth Rudenbrandt | Technical Product Manager, Fagerhult